Flexible Fix. Tough Bonds.

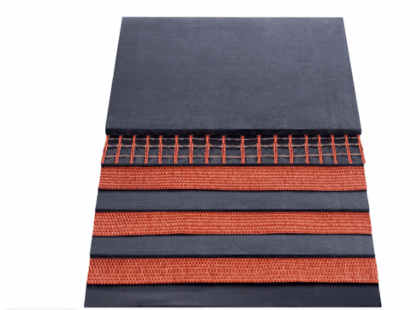

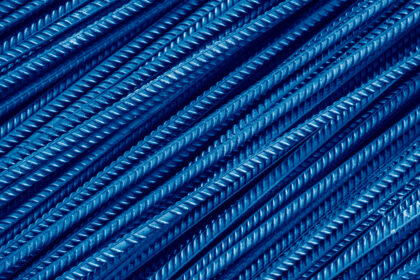

Plastisol adhesives are heat-activated, vinyl-based bonding agents engineered for high-performance industrial use. Supplied in liquid or paste form, they are easily applied through screen printing, rolling, or dispensing methods. Upon curing at elevated temperatures (typically 150–200°C), they form firm, flexible, and resilient bonds on a wide range of substrates.

Protech’s plastisol adhesive series offers repositionability before curing, allowing for accurate alignment during assembly. These heat-activated, vinyl-based adhesives are suitable for screen printing, roll coating, or dispensing onto various substrates, including textiles, foams, metals, and plastics. With customizable formulations and consistent performance, they are ideal for high-speed, high-volume manufacturing.

Features

- Heat-Activated – Cures at 150–200°C to form strong, permanent bonds

- Flexible Formulation – Based on vinyl resins, offering elasticity and resilience

- Customizable – Adjustable tack, viscosity, cure time, and hardness

- Application Versatility – Available in liquid or paste form for screen printing, rolling, or dispensing

- Reworkable Before Cure – Allows repositioning and adjustments before heat activation

Downloads

Download all files associated with our Plastisol Adhesive series.

Technical Properties

Applications

Solutions

Explore Our Plastisol Adhesive Solutions: We offer heat-activated, vinyl-based plastisol adhesives engineered for strong, flexible, and durable bonding across a wide range of substrates. Customizable in tack, viscosity, cure time, and hardness, these adhesives are ideal for demanding industrial and high-volume manufacturing environments. If you don’t see your specific requirement listed, contact us—our team is ready to help you find or develop the perfect solution for your application.