Shape, Stretch, and Strengthen with Latex.

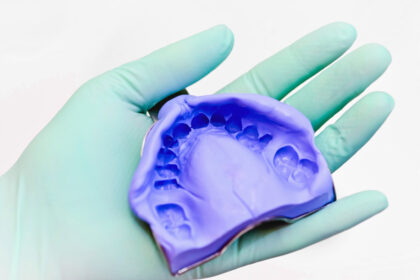

Latex molding involves building up part thickness by dipping, spraying, or coating molds with liquid latex, allowing for the creation of hollow, lightweight, and flexible parts without seams or joints. These formulations are engineered to conform precisely to mold shapes, resulting in smooth, uniform surfaces and strong, elastic structures.

Available in both natural rubber (NATLEX) and synthetic (SYNLEX) options such as nitrile and neoprene, latex molding can be tailored for specific performance requirements. It is widely used across industries including healthcare, industrial equipment, automotive components, and consumer goods. The process enables the production of durable, seamless parts with customizable strength, elasticity, and chemical resistance.

Features

- Post-Curing Compatible – Supports leaching and vulcanization to improve material strength and safety

- Exceptional Durability – Offers high tear strength, puncture resistance, and long-lasting performance

- Seamless Barrier Protection – Produces airtight and watertight parts for medical, industrial, and inflatable use

- Flexible Production – Ideal for fast prototyping and low-volume runs with economical tooling

- Additive-Friendly – Compatible with antimicrobial additives for healthcare and hygiene-sensitive applications

Downloads

Download all files associated with our Latex Molding series.

Technical Properties

Applications

Solutions

Precision-Engineered Latex Molding Systems: Our natural and synthetic latex formulations are designed for seamless, flexible, and durable molded parts created through dip molding, spraying, or coating. Ideal for medical, industrial, automotive, and consumer applications, these systems offer customizable thickness, cure time, and performance properties. We work closely with customers to tailor solutions that meet specific production and end-use requirements.