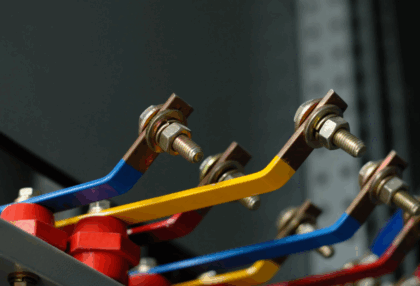

Seamless Coating. Superior Grip.

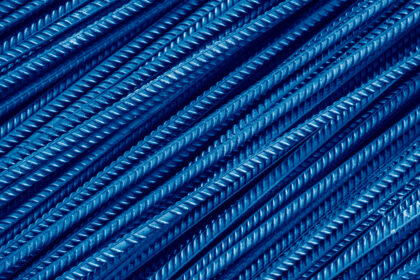

Plastisol is a versatile solution that serves both protective and decorative purposes across a wide range of industries. Commonly used as a coating for metal parts or as a molding material for open-ended components, it enhances grip, insulation, durability, and appearance. From tools and automotive parts to industrial equipment and consumer goods, Plastisol delivers long-lasting performance in demanding environments.

Dipping series is efficient for covering complex shapes and high-wear parts. These heat-activated vinyl coatings form a flexible, resilient layer that resists impact, moisture, and chemicals. With options to customize texture, color, and thickness, plastisol offers a cost-effective way to achieve both functional protection and a high-quality finish tailored to your application.

Features

- Smooth, Even Coverage – Coats curves, edges, and complex shapes with a uniform, high-quality finish.

- Dip Molding Capability – Gels and fuses onto molds or mandrels for the production of open-ended components.

- Protective Barrier – Shields against moisture, chemicals, and harsh environments to preserve performance.

- Durability & Impact Resistance – Resists abrasion, impact, and daily wear to extend product life.

- Dual Functionality – Combines molding and coating capabilities for efficient, high-performance manufacturing.

Downloads

Download all files associated with our Plastisol dipping series.

Technical Properties

Applications

Solutions

Versatile Plastisol Dipping Solutions: Our plastisol dipping series is designed for heat-activated coating of tools, grips, handles, caps, and complex shapes. These vinyl-based formulations provide a smooth, durable, and flexible finish with excellent adhesion and resistance to impact, moisture, and chemicals. Customizable in viscosity, thickness, and hardness, they support both functional and decorative applications. Looking for a specific solution? Our team is ready to help you customize the perfect fit.