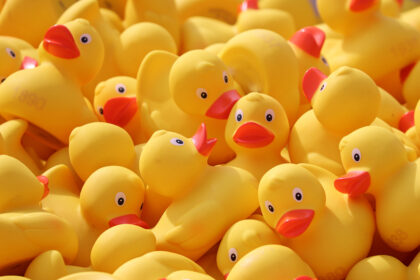

Form Your Vision. Mold with Plastisol.

Plastisol molding is a highly versatile process used to produce flexible or rigid parts by forming material inside hollow molds. The plastisol is poured or rotationally dispersed within the mold, then heated to cure the vinyl resin and plasticizer. This method is ideal for creating components with complex geometries and fine details, thanks to its excellent flow characteristics and controlled viscosity.

Curing typically occurs at elevated temperatures between 150–200°C, allowing the molded part to achieve full adhesion and mechanical strength. The result is a durable, flexible product with customizable shapes, textures, and finishes—suitable for applications such as grips, gaskets, caps, and specialty components across industrial, automotive, and consumer markets.

Features

- Customizable Hardness and Flexibility – Finishes can range from soft and rubbery to rigid and structural, tailored to your specific needs.

- Cost-Effective for Low Volumes – Low tooling costs make it ideal for short runs and custom or prototype parts.

- Color & Texture Versatility – Available in a wide range of colors and surface finishes to meet aesthetic or functional goals.

- Seamless Complex Shapes – Supports the production of intricate, joint-free parts with complex geometries.

Downloads

Download all files associated with our Plastisol molding series.

Technical Properties

Molding Methods

Applications

Solutions

Flexible Plastisol Molding Solutions: Our plastisol molding series offers heat-activated, vinyl-based compounds designed for flexible, durable molded parts. Ideal for grips, gaskets, seals, and custom components, these formulations provide excellent surface detail and mechanical strength. With adjustable viscosity, hardness, and cure profile, they’re tailored to meet a wide range of molding needs. Need something specific? Our team is here to help.