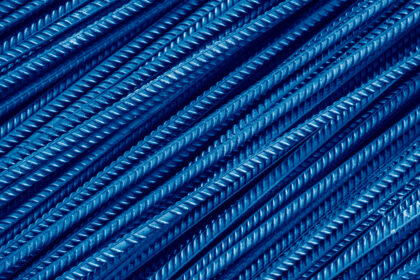

Anti-Gassing Power. Surface Perfection.

Anti-gassing powder coatings are specially formulated to prevent defects such as pinholes, craters, and bubbles that can occur when gases trapped in porous metal substrates, like cast aluminum or galvanized steel, escape during the curing process. These coatings help ensure a smooth, uniform finish by allowing trapped gases to escape before the film fully cures, significantly improving both aesthetics and long-term performance. Anti-gassing solutions are essential for applications where coating quality and surface integrity are critical.

AG-KOTE is Protech Group’s anti-gassing powder line designed for coating porous substrates like cast metals and galvanized steel. Its unique formulations require low curing temperatures, resulting in fewer surface defects such as craters and bubbles, while also offering energy and cost savings. With advanced degassing technology, AG-KOTE ensures a smooth, high-quality finish, providing excellent adhesion, durability, and aesthetic appeal for demanding industrial applications.

Features

- Degassing Additives – Minimize pinholes and surface defects.

- Low-Temp Cure – Ideal for ultra-sensitive substrates.

- Smooth Finish – Ensures uniform, blemish-free coating.

- Strong Adhesion – Bonds well to porous and tricky substrates.

- High Coverage – Improves efficiency and reduces rework.

- Versatile Use – Ideal for industrial and outdoor parts.

- Chemistry Options – Available in polyester, epoxy, and hybrids.

- Boosts Productivity – Reduces defects and downtime.

Downloads

Download all files associated with our anti-gassing thermoset powder coatings, AG-KOTE.

Technical Properties

Applications

Solutions

Explore Our Anti-Gassing Coating Solutions: We offer advanced, anti-gassing thermoset coatings for a diverse range of applications. If your specific need isn’t listed, feel free to contact us—we’re here to help.