Static Control. Solid Protection.

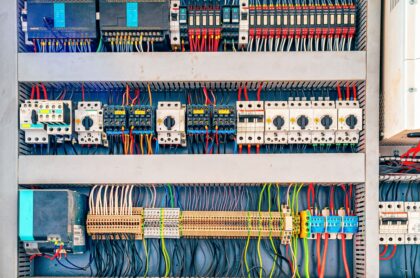

Electrostatic discharge (ESD) issues are commonly encountered in the electronics industry, where products can sustain damage due to electrostatic charges. Even a mere 100 volts can potentially harm an electronic component. To mitigate these risks, it is essential to use electro-dissipative coatings as a protective barrier.

ESD-KOTE is a patented thermoset powder coating solution designed to minimize the risk of shock by continuously conducting and dissipating static electricity on surfaces while slowing the charge transfer rate. ESD-KOTE is created by blending an electrically conductive pigment with a non-conductive resin binder. The binder ensures the paint’s cohesion and offers adhesion, while the conductive filler establishes the electrical pathway. This coating effectively channels static electricity to a connected ground, preventing sparks and protecting electronic components during use or storage.

Features

- Static Dissipation – Prevents static buildup.

- ESD-Safe Resistivity – Meets 10⁵–10⁹ ohms range.

- Durable – Resists wear and impact.

- Chemical Resistant – Handles cleaners and solvents.

- Long-Lasting Performance – Maintains ESD properties over time.

- Finish Options – Available in smooth or textured.

- Low-VOC – Eco-friendly and solvent-free.

- Color Choices – Custom colors available.

- Safe for Sensitive Areas – Ideal for electronics and cleanrooms.

Downloads

Download all files associated with our electrostatic discharge thermoset powder coatings.

Applications

Solutions

We offer specialized Electrostatic Discharge (ESD) thermoset powder coatings designed to protect sensitive equipment and components in environments that are sensitive to static. Our solutions combine effective static control with durable finishes, ideal for applications in electronics, telecommunications, cleanrooms, and industrial settings.